In the age of intelligent mobility, vehicle safety innovation is no longer optional—it’s the standard. From advanced driver-assistance systems (ADAS) to autonomous driving, cameras play a vital role in real-time monitoring, collision prevention, and traffic awareness. Behind these innovations stand the ODM car camera factories, whose technical expertise and customization capabilities drive safer, smarter vehicles worldwide.

For automotive manufacturers, fleet managers, and international distributors, understanding how these factories support innovation can lead to stronger product lines and a competitive edge.

The Role of ODM Car Camera Factories in Modern Vehicle Safety

ODM (Original Design Manufacturer) car camera factories go beyond simple production—they create tailored imaging solutions that integrate with vehicle electronics and safety systems.

Key Contributions Include:

-

Customized Camera Modules: ODM factories design lenses, sensors, and housings to meet specific vehicle types—whether passenger cars, trucks, or buses.

-

Integration Expertise: They ensure cameras work seamlessly with ADAS, parking systems, or blind-spot detection features.

-

Technology Upgrades: Continuous R&D keeps pace with trends like AI image recognition and night vision optimization.

-

Compliance & Testing: Reputable manufacturers meet ISO/TS 16949 and automotive-grade AEC-Q100 standards for quality assurance.

By leveraging advanced design and manufacturing, ODM car camera manufacturers empower automakers to achieve both reliability and scalability.

How ODM Car Camera Factories Drive Safety Innovation

ODM camera suppliers are catalysts for automotive innovation through three major pillars—design flexibility, manufacturing precision, and AI-enabled vision technology.

1. Design Flexibility for Custom Applications

ODM car camera factories provide modular platforms that adapt to various automotive needs:

-

Multi-angle vision systems for 360° AVM (Around View Monitoring).

-

High-resolution sensors for lane departure and obstacle detection.

-

Ruggedized casings for harsh industrial or commercial fleet environments.

This flexibility helps OEMs shorten development cycles and reduce tooling costs—ideal for fast-changing automotive projects.

2. Precision Manufacturing for Durability

Vehicle cameras must endure vibration, dust, and extreme temperatures. ODM factories employ:

-

Robotic assembly lines for high consistency.

-

Automated lens alignment to guarantee focus accuracy.

-

IP67-rated protection for outdoor reliability.

Through rigorous testing, including salt spray, shock, and thermal cycling, ODM factories ensure that every camera withstands real-world challenges.

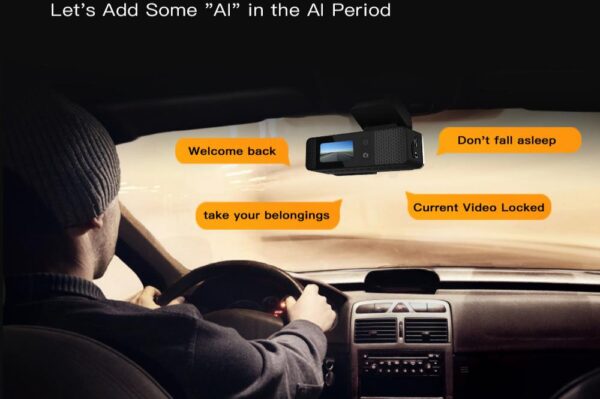

3. AI and Infrared Integration for Smart Safety

The next generation of car cameras combines infrared night vision and AI object detection. ODM car camera manufacturers are integrating these into mass production to improve safety:

-

Infrared sensors enhance visibility during low-light driving.

-

AI algorithms identify pedestrians, vehicles, and road signs in milliseconds.

-

Edge computing modules reduce latency for real-time safety decisions.

This convergence of hardware and intelligence forms the foundation of autonomous driving systems.

Benefits of Partnering with a Reliable ODM Car Camera Factory

For automotive suppliers and B2B buyers, selecting the right ODM partner can transform efficiency and innovation.

Main Advantages:

-

✅ End-to-End Service: From concept design to assembly and quality control.

-

✅ Cost Efficiency: Lower R&D and production costs through established OEM frameworks.

-

✅ Scalable Production: Rapid customization for bulk or specialized orders.

-

✅ Technical Support: Firmware tuning, optical calibration, and system testing.

Partnering with a reputable ODM car camera factory helps manufacturers accelerate time-to-market while maintaining strict safety and quality standards.

Key Features to Look for in an ODM Car Camera Supplier

When evaluating suppliers, B2B customers should prioritize the following:

-

Certification & Compliance: Look for IATF 16949, ISO 9001, and CE certifications.

-

R&D Strength: A capable engineering team with in-house testing labs.

-

Global Experience: Proven export history to automotive markets in Europe, North America, or Asia.

-

After-Sales Support: Responsive service for firmware upgrades or technical troubleshooting.

These features indicate a supplier’s reliability and readiness for long-term cooperation.

Real-World Applications of ODM Car Camera Systems

ODM-designed vehicle cameras are widely used across sectors:

-

Passenger vehicles: Lane keeping, parking assistance, blind-spot monitoring.

-

Commercial fleets: Rear-view monitoring, collision avoidance, telematics data integration.

-

Law enforcement vehicles: 24-hour recording and facial recognition.

-

Construction and logistics: Heavy equipment navigation and perimeter safety.

By combining functionality, safety, and smart analytics, these cameras enhance both driver confidence and operational control.

Conclusion

In today’s connected mobility era, ODM car camera factories play a critical role in driving vehicle safety innovation. They blend optical engineering, AI integration, and mass production expertise to meet evolving automotive demands.

For manufacturers, B2B buyers, and resellers, partnering with a trusted ODM supplier ensures access to cutting-edge car camera technology, scalable manufacturing, and superior quality—all essential for success in the global automotive market.

FAQs

1. What is the main advantage of working with an ODM car camera factory?

You gain access to customized, high-quality cameras designed for specific vehicle systems, reducing development time and cost.

2. How do ODM car camera manufacturers ensure safety compliance?

They follow automotive-grade standards like IATF 16949, conduct environmental testing, and perform optical calibration for precision.

3. Can ODM factories support small-batch or custom projects?

Yes. Many offer flexible production runs, ideal for new vehicle models, fleet upgrades, or specialized B2B applications.